A high-quality cosmetics filling machine could potentially be a game-changer in the fiercely competitive cosmetics industry. These machines are made to facilitate not only the production of products in assembly lines but to further enhance the quality of the product and bring it into the market as soon as possible. The video posted above goes on to break down why the perfect cosmetic filling machine is a sound investment. Here, we explore in depth what makes a leading cosmetic filling machine worth every dime.

Overclocking: Best in Class Precision and Consistency

An impressive cosmetics filling machine has an unprecedented precision in the amount of product poured into the package. Most machines have an accuracy of approximately ±0.5% of the target fill volume, allowing each product to be filled with a precise amount of product (liquid, cream, gel, etc.) The higher the accuracy, the less likely material will be wasted, and the potential for batch-to-batch consistency, which is crucial for brand image and potentially staying in business.

Scalability for Different Types of Products

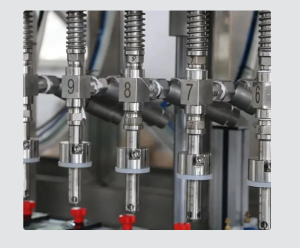

A cosmetic filling pump, a low-viscosity gear pump suitable for filling cosmetic products in the cosmetics industry, has unparalleled versatility. Our modern machines are able to accommodate a vast variety of product viscosities and packaging types and sizes, including vials for samples and large containers. This is versatile manufacturing that enables manufacturers of cosmetics companies to use one machine several times for different products thereby streamlining the operation and reducing the number of separate equipment.

Improved Operational Efficiency

Having an amazing filling machine goes a long way when it comes to production efficiency. State-of-the-art models can handle throughputs of up to 200 containers per minute, depending on the product and container size. In addition, it is this speed that allows you to keep up with the market when demand peaks, as it can happen at the time of sales or product launches.

Improved Product Integrity

In the cosmetics world, product integrity is of the utmost importance, as the state of the products being sold has a direct impact on how consumers feel about you. For a start, the best filling machines come with inherent protections, including sensors that prevent filling in the absence of a bottle at the filling point and sophisticated control measures that minimise spillage and contamination while filling. These qualities guarantee that every product arrives in the hands of the end user in pristine condition, improving user satisfaction and shoring up a brand's trustworthiness in the process.

Ready for a Long-Term Game

Therefore even if you have to come up with a larger lump sum of investment at once for a top-tier cosmetics filing machine, in the end it pays off massively. These units are designed to be rugged and durable with elements that can stand up to the punishment of regular operation. Moreover, their handling capacities make for real money over time in saving, and that saving money spent unnecessarily on costly recalls or disappointing frustrated ends users bore a compromise in product flow or contamination.

Accessibility and Compliance

Cosmetics Filling machines are of high quality and are designed for easy maintenance. Many are built with components that are simple to clean and that have modular parts that are interchangeable - reducing downtime if service is needed. What is even better, is that these machines conform to industry standards, to be completely compliant with the laws and regulations, which is essential for a cosmetics manufacturer.

Securing Competitive Edge

In summary, it is a must for a cosmetics business to own a cosmetics filling machine of premium quality if it intends to scale its operations, keep the product quality constant and stay ahead in the competition in the market. These machines provide precision, efficiency, and reliability, all of which do a great job of not only enhancing daily output but also contributing to the long-term success enjoyed by businesses.